T&D Times - June 2020

Don't Overlook Your Aging Substations

Substation Structure Life Extension Solutions

For years, Osmose has been assessing and restoring steel transmission poles and towers. The process used for transmission asset management has allowed Osmose to gather an extensive amount of steel and concrete degradation data, all while restoring and extending the lives of thousands of steel transmission structures. Years of providing steel transmission asset management services has given Osmose unparalleled experience and allowed engineering designs and restoration drawings to be standardized to provide measurable variables for identifying reject steel structures and concrete components.

For years, Osmose has been assessing and restoring steel transmission poles and towers. The process used for transmission asset management has allowed Osmose to gather an extensive amount of steel and concrete degradation data, all while restoring and extending the lives of thousands of steel transmission structures. Years of providing steel transmission asset management services has given Osmose unparalleled experience and allowed engineering designs and restoration drawings to be standardized to provide measurable variables for identifying reject steel structures and concrete components.

When Osmose was tasked with developing restorations for rejected steel and concrete structure components within substations, it was clear that the original standard designs for steel poles and towers would not suffice. Most substation structures and foundations are configured quite differently than transmission steel towers and poles. Codes governing the design of substation structures also differ from transmission structure design requirements. Osmose steel tower and pole restoration designs are frequently adapted to the differing geometries and configurations of substation structures. These adaptations are done by utilizing new design analyses to adapt the existing transmission restoration designs. When the substation structure configuration or geometry strays too far from our standard steel restoration designs, Osmose will typically develop a new stand-alone design for the substation structure. Regardless of the development process for a final substation restoration design, the result is that the new design can be added to Osmose’s unique library of substation standards.

The following are a few examples of designed restorations:

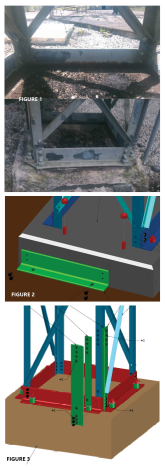

The base horizontal member is vital to the stability of the structure because it acts as base plate to connect the post legs to the concrete foundation through anchor bolts. Due to a lack of drainage inside of the box structure frame, corrosion is often present on the interior of these base horizontal members – as shown in Figure 1. The most effective solution for this type of reject is to perform a substation base horizontal replacement – shown in Figure 2. This restoration involves removing the base horizontal member and all existing hardware that connects the base horizontal to the post leg and the concrete foundation, excluding the cast-in place anchors themselves. Likewise, precautionary measures are taken to avoid damage to the cast-in-place anchor. To complete the restoration, the base horizontal member and associated hardware are replaced with like-for-like components and coated.

Like base horizontal members, post legs may also experience corrosion near the base of the structure. Again, this is due to the tendency of the box structure to retain or trap moisture within its confines. There are multiple restorations for corroded post legs. Each restoration type is typically dependent on the layout of the original structure. One substation-specific restoration designed by Osmose Engineering for post legs, which are a part of the box structure, is shown in Figure 3. This substation splice is a variation of the original standard restoration designed for towers - the OSMO-MATIC splice plates. Updates to the sizes and lengths of filler and splice plates, the bolt hole configuration, and installation procedures are engineered to accommodate typical substation box structure frames.

The two restorations shown above are just a glimpse into the full catalog of completed substation restorations. With each new substation, new structures configurations are encountered and, subsequently, new design and restoration challenges arise. Osmose is fully prepared to alter existing or design new restorations to fit the needs of such structures.

For information about substation restorations, contact your local Osmose professional or email steel@osmose.com.

.png?width=243&name=Osmose-logo-(white).png)