Cyclical Assessment Program

Cyclical assessment yields improved safety, reliability, and excellent return on investment

The Situation

Operating and maintaining transmission systems requires regular intervals of vigilant observation to maintain the safety and reliability of all structures. A commonly overlooked concern with steel structures is detecting any below-grade corrosion activity and the rate at which it is occurs. When active corrosion is present and rapidly occurring, it can put large transmission systems at risk and significantly reduce reliability.

A utility in east Tennessee initiated a pilot assessment project to determine the belowgrade condition of their transmission system, which included more than 40,000 steel structures. This pilot assessment included the excavation of 240 towers, which revealed evidence of below-grade corrosion far more severe than anticipated. It was determined that one-third of the towers displayed heavy corrosion and would require restoration. The utility decided that a cyclical, comprehensive inspection program would provide the greatest long-term protection and extend the service life of the assets. The cyclical inspection program included a full excavation of each tower’s foundation and the application of protective coatings.

The Solution

When executed correctly and on a cyclical basis, a groundline and below-grade assessment and restoration program will improve system safety and reliability, extend the service life of steel transmission structures, reduce restoration costs, and prevent premature tower replacements. The cost of a cyclical program is minimal when directly compared to events that require an outage, whether planned or unplanned.

When executed correctly and on a cyclical basis, a groundline and below-grade assessment and restoration program will improve system safety and reliability, extend the service life of steel transmission structures, reduce restoration costs, and prevent premature tower replacements. The cost of a cyclical program is minimal when directly compared to events that require an outage, whether planned or unplanned.

Assessment and Mitigation

Osmose’s recommended assessment and mitigation program consists of a full 18 to 24 inch excavation, where deterioration is most likely to occur, and a comprehensive structural assessment of each tower member in the deterioration zone. Additionally, several environmental tests are performed on the surrounding soil, which allows the likelihood and severity of future corrosion to be determined. Structures are categorized based on specific criteria of the selected corrosion rating system. In this utility’s case:

- Tower legs categorized in Condition A and Condition B received a protective coating to mitigate further corrosion

- Tower legs rated as Condition C, Condition D, and Priority received engineered restorations. In addition to the restoration, the affected tower legs received protective coatings to prevent the on-set of future corrosion.

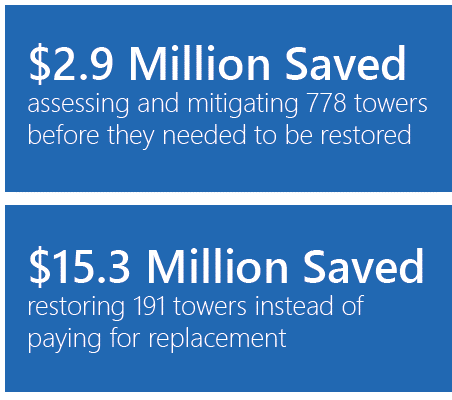

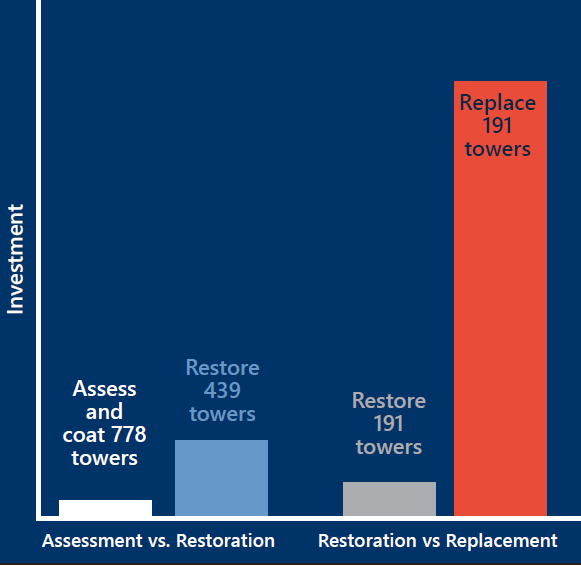

Of the 1,034 steel towers and poles that were assessed in that year, 778 towers were coated and required no further action. This included 439 towers listed as Condition B (moderate corrosion) which, without assessment and coating, would have migrated into Condition C (significant corrosion and 10-25% section loss) and eventually Condition D (severe corrosion) requiring restoration in the coming years. Assessing and coating those 778 towers that same year, versus potentially restoring 439 of them in the future, saved the utility more than $2.9 million in restoration costs.

Restoration

This utility’s network of transmission structures is comprised of different tower types, with each requiring a specific restoration. Osmose standard restorations are designed to meet structural loads that account for line angle, environmental conditions, and post leg capacity for each specific structure type. These rehabilitation solutions are designed to meet American Society of Civil Engineers (ASCE) standards to restore original strength and increase capacity when greater strength is required. This structure-specific restoration approach reduces the need for costly, heavy equipment at each structure site and is extremely cost effective when compared to replacement. Most importantly, restorations are designed to be performed without the need for an outage or service disruption.

This utility’s network of transmission structures is comprised of different tower types, with each requiring a specific restoration. Osmose standard restorations are designed to meet structural loads that account for line angle, environmental conditions, and post leg capacity for each specific structure type. These rehabilitation solutions are designed to meet American Society of Civil Engineers (ASCE) standards to restore original strength and increase capacity when greater strength is required. This structure-specific restoration approach reduces the need for costly, heavy equipment at each structure site and is extremely cost effective when compared to replacement. Most importantly, restorations are designed to be performed without the need for an outage or service disruption.

In the same year, 191 towers rated as Condition C, D, and Priority were restored. Without restoration, those 191 towers would have continued to deteriorate, eventually requiring replacement. Rehabilitating those towers in that same year versus replacing them later allowed the utility to avoid more than $15.3 million in replacement costs!

Adding years of dependable service life to steel structures defers repairs and replacements, avoiding unnecessary operations and maintenance and capital spending.

.png?width=243&name=Osmose-logo-(white).png)