T&D Times - April 2021

Capture a 3-D Analysis of Your Steel Structures

Capture a 3-D Analysis of Your Steel Structures

When was the last time you accurately scanned and assessed your transmission structures? Was the code you used to assess the risk the most recent or was it from when the structure was built decades ago?

The transmission industry is being greatly impacted by Light Detection and Ranging or LiDAR for inspecting and analyzing structures. This innovative technology, through scanners and software, can solve advanced problems and predict how steel poles and towers will respond to catastrophic loads, and gives utilities information on how to optimize restorations both at grade and overhead to become less conservative.

LiDAR practices are at the forefront in many industries across the modern workforce. LiDAR is being integrated in modern day iPhones, transportation forensics for major roadway crashes, real estate projects, commercial buildings, and much more. This versatile technology allows the professional to take a 3-D snapshot of their work environment which provides tools for analysis, planning, maintenance, and inspection. This gives the utility industry multiple avenues on how to scan a structure: terrestrial (ground-based or static), aerial (UAV or helicopter), and mobile (cars or backpacks).

This technology provides a more accurate profile for risk assessments and reliability for the circuit by supplementing your existing documentation and comparing your structures to current day industry standards. With the ever-changing technical and environmental landscape, the reality of funding a safer future for today’s infrastructure cannot be delayed.

How does LiDAR work?

LiDAR scanners and sensors measure the distance to an object by using laser light, and then measures the time it takes for the light to return to the sensor. The laser light acts like a boomerang, only reflecting back what the operator or user sees in their line of sight. Changes in laser wavelengths and return times can be combined to represent 3-D accurate point clouds or visual models of the structure.

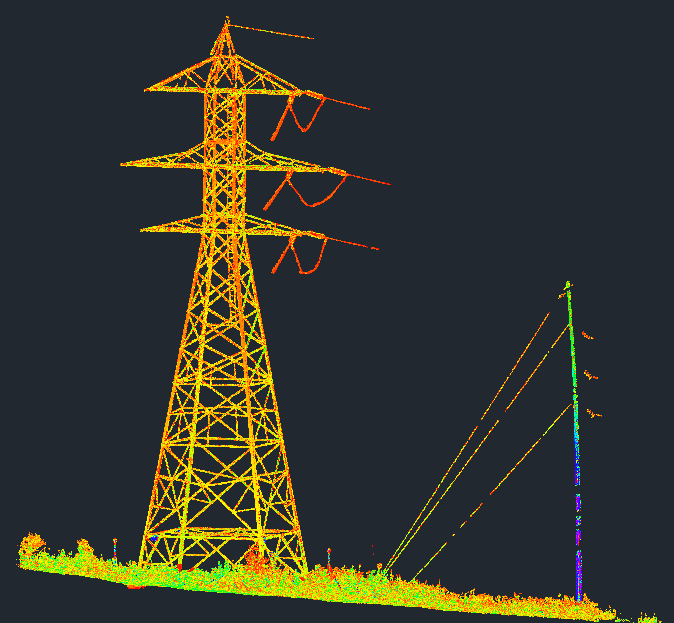

Figure 1: Lattice tower for LiDAR study

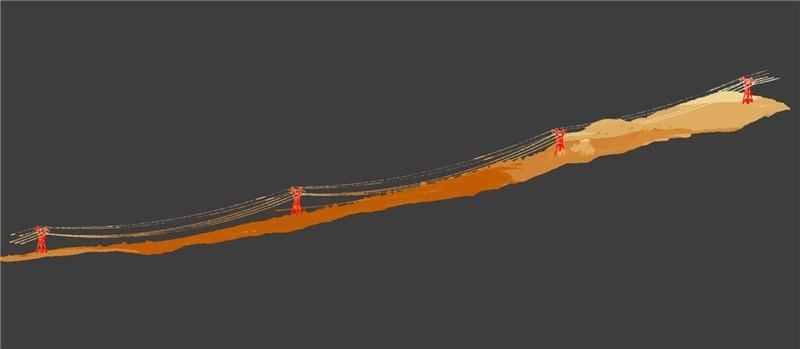

Using LiDAR, large amounts of collected data generate an overall resemblence of the structure, lines, and surrounding topography. With the onset of UAV technology, aerial LiDAR has improved due to the flight path proximity and flight speed. UAV LiDAR typically has a relative accuracy of 3 to 5 centimeters when performing large scale scans. This approach is beneficial for collecting wireframes for the overall structure, line angles, elevations, vegetation, heights, and conductor clearances. This is proven for advanced surveying for transmission lines, however, more accuracy would be needed for structural analysis and detailing.

Figure 2: Unmanned aerial vehicle (UAV) LiDAR sample

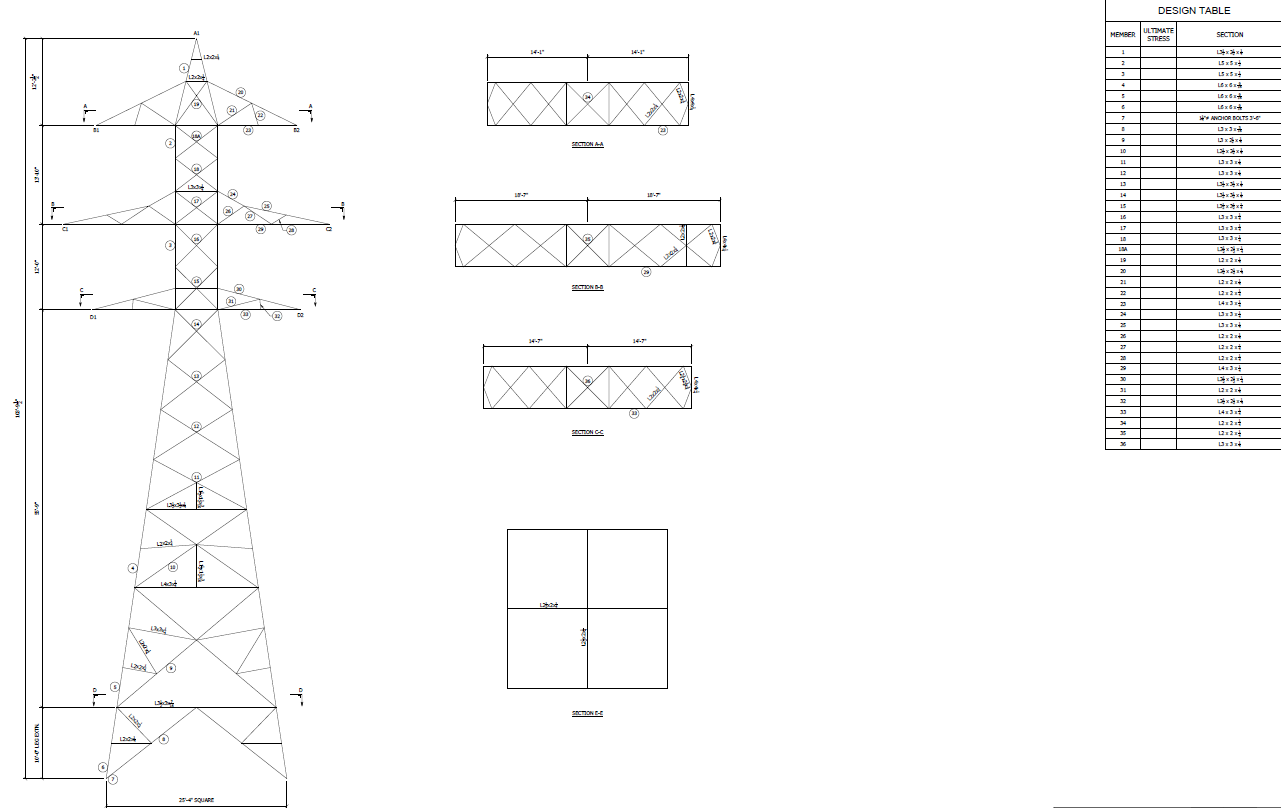

For the most accurate detailing, terrestrial scanners produce highly accurate point clouds which can be used for modeling towers and 3-D structural analysis. LiDAR creates a safe alternative to tower climbing inspections and gives customers high dynamic range (HDR) imagery, damage detections, and extremely accurate tower dimensions. Weak spots like connection damage, structural deformations, and highly stressed members may be detected and resolved for restoration or strengthening of the structure. Current day health, resiliency, and strength of the structure can be fully analyzed and reported to the utility. One of the major benefits is that all detail and design drawings can either be replenished from over 50 years ago, or even created from scratch with modern industry standards.

With improved technology and sophisticated sensor capabilities, advanced solutions are available to address everyday problems. The increase in accurate data for each utility leads to better risk assessment and improved reliability. LiDAR technology is a solution many clients find helpful in their portfolio of asset life extension methods. With the ever-changing technical landscape, it is an exciting time for engineering the future of infrastructure assessments and restorations within the T&D industry.

Figure 3: Terrestrial LiDAR point cloud of lattice tower

Figure 4: Design drawing for existing tower

.png?width=243&name=Osmose-logo-(white).png)